<h4>Caliper logging</h4>

The caliper probe, a simple mechanical device, whose main functionality is to measure the internal diameter of a borehole or casing string within a borehole. Another purpose of a caliper arm is to push a section of a probe against the side of the borehole (for example density logging), known as sidewalling.

Additional data measured from a caliper log includes:

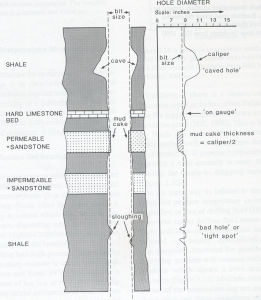

- The roughness or rugosity of the borehole wall. Soft rocks can be washed away significantly by the drilling process giving a rough, uneven caliper measurement. Typically hard rocks show a very smooth caliper log.

- The measured diameter can be used for the borehole environmental correction of other logs.

- It can also be used as an indicator of geophysical log quality.

- Identify fractures in hard rock.

- Caliper logging inside a casing string will confirm the internal diameter but also build of material on the inner surface and/or areas where the casing may have broken or failed.

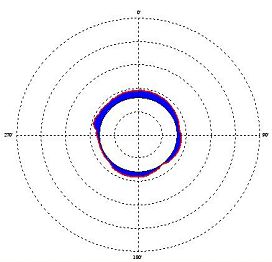

- More specialised caliper probes can measure if the borehole’s circular cross section changes. Called borehole ovalisation, this can give important insitu stress directions for underground mining.

- In the oil industry, the caliper log can be used to indicate build-up of mud cake which in turn can be used to infer permeability in the rock.

<h4>Two/three arm Calipers used in mineral logging</h4>

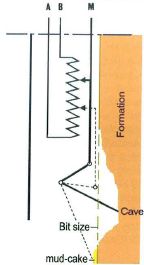

These probes have separate arms to measure borehole diameter but importantly the arms are all linked to a central shaft in the probe where movement through a potentiometer electronically digitises the borehole diameter. The key here is that if you push in one arm (assuming caliper arms have been opened), all other arms go in by the same amount – the caliper arms do not independently measure diameter.

So inclined boreholes and without centrallisers on the probe/stack, it is likely the two or three arm caliper will measure under the drill or cased diameter because of the probe weight pressing against the caliper arm on the low side..

<h4>Four arm calipers</h4>

Four arm caliper probes or two, two arm calipers joined together are available where the individual (or pair of caliper arms) arm measurement are recorded – the arms act independently. This is an important measurement to enable identification of borehole ovalisation which is an indicator of uneven stress regimes in the sub surface – an important measurement for underground mining.

<h4>Acoustic Scanners</h4>

Taken from the oil industry, acoustic scanners (televiewers) used in borehole imaging can be used as a multi-fingered caliper probe for internal casing measurements or borehole ovalisation. Each sample of an acoustic scanner can be used as a caliper arm. As acoustic scanners can sample between 90 up to 360 times per head rotation (a 2 – 3mm vertical distance), this makes for a highly accurate caliper measurement.