Gamma logging for uranium exploration and mining is an established technique for producing a rapid and cost effective depth based profile in a borehole of uranium ore grade.

The most common measurement systems involve a scintillation system where gamma photons are converted to light energy enabling digital count rate conversion. The most common crystal used in the scintillation system is sodium iodide. Research has been undertaken into other crystals (such as the Brilliance project) with limited success.

Common Gamma Logging Techniques

The most common gamma logging technique is “total gamma” logging where the whole gamma radiation energy spectrum is measured. The size of the crystal used in the scintillation system of a total gamma probe can vary depending upon the requirement for sensitivity versus potential saturation of the scintillation system, Crystal sizes approaching 25mm diameter and 50mm length are common.

As gamma logging evolved, hybrid gamma probes were developed and made available to investigate specific areas of gamma radiation and/or to redefine the measurement range:

- Spectral gamma logging measures count rates within the scintillation system with certain specific energy windows of the gamma radiation spectrum with the aim of quantifying the amount of the common naturally occurring isotopes of Potassium, Uranium and Thorium. Quite a slow rate of logging due to the large crystal size and low count rates, it has been particularly useful in identifying the presence of Uranium over Thorium of vice versa.

- Filtered gamma logging uses thin layers of a range of metals (typically lead, copper or brass or combinations) around the scintillation detection system as a shield against low energy gamma radiation. The low energy gamma radiation is thought to have a negative effect upon the uranium ore grade measurement particularly where radon gas is produced.

Calibration of gamma probes is an important part of process of producing a depth based profile of uranium ore grade.

Calibration

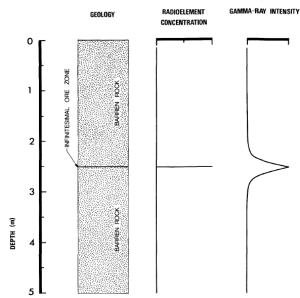

The calibration process requires a borehole environment with a range of accurately known grades of Uranium surrounding the borehole. The uranium bearing zone needs to be a minimum thickness and a minimum diameter to allow an infinitesimal response – meaning the probe (instrument) sees only the uranium grade and nothing else.

- Typical dimensions of the calibration environment are 1m vertical thickness and greater than 2m in diameter. This is achieved at the Adelaide Models through models AM1, 2, 3 and 7.

- Instrument factors to calculate during the calibration process are detector deadtime and instrument K factor.

- The calibration unit is eU3O8 where the e prefix indicates derivation from gamma logging.The calibration process requires a borehole environment with a range

Borehole Environmental Corrections.

Environmental corrections need to be calculated at the time of calibration or later in the field. The corrections are required because of any change in logging environment conditions from the calibration to the uranium exploration or mining project. These environmental corrections include:

- Changes in the borehole diameter.

- Changes in the presence of fluid/air in the borehole.

- The presence of drill rods and/or casing at the time of acquisition.

- The density of the rock surrounding the borehole.

- All the above affect the gamma probe response

Data Processing – Deconvolution.

In addition to environmental correction of depth based gamma uranium grade data, some data processing techniques have been developed, the chief of which is the deconvolution of the gamma log. The ideal response of a gamma log is shown below

For a thin uranium bearing zone in a rock sequence otherwise barren, the plot of Uranium concentration becomes a broader based peak due to how we make the measurement and where we take the measurement. These effects can be summarised as:

- Geological impulse response which reflect where the measurement was taken, such as gamma ray energy, formation density, fluid content etc.

- System function response reflects details of the data acquisition system such as crystal size, housing thickness, shielding etc.

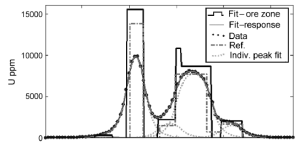

As the above effects are convolved (mixed) with the depth based uranium grade measurement made during gamma logging. The aim of deconvolution is to “taken away” these effects and give the cleanest depth based uranium grade measurement.

Disequilibrium

Uranium disequilibrium is a concern for some uranium explorers where the uranium system is within a sedimentary environment with geologically recent groundwater circulation. Under such conditions, gamma logging results can be affected by the movement of uranium with respect to its daughter products. These concern relates to gamma logging responding to the uranium daughter products and not the uranium itself and hence the potential for false positives or false negatives.

- Early techniques to overcome the disequilibrium effect was to compare gamma logging grades to laboratory grades from core and calculate a disequilibrium factor to be applied to the gamma logs.

- Neutron logging probes (PFN) were developed to directly detect the uranium. The early models of the PFN were expensive, had a poor reliability record and poor repeatability at low uranium grades proved problematic and affected the use of the logging technique.

- More advanced neutron activation logging techniques (APFN) are being developed to increase reliability of the method and measure a geochemical profile of the formation.

- Advanced gamma-gamma density logging techniques are being developed to measure the geochemical profile of the formation with a view to directly detecting uranium through photo electric capture.