<h4>Managed Aquifer Recharge Schemes</h4>

An interesting presentation at a recent groundwater forum showed the increasing popularity (in the arid conditions of South Australia – a necessity) of Managed Aquifer Recharge schemes.

<h4>What is MAR?</h4>

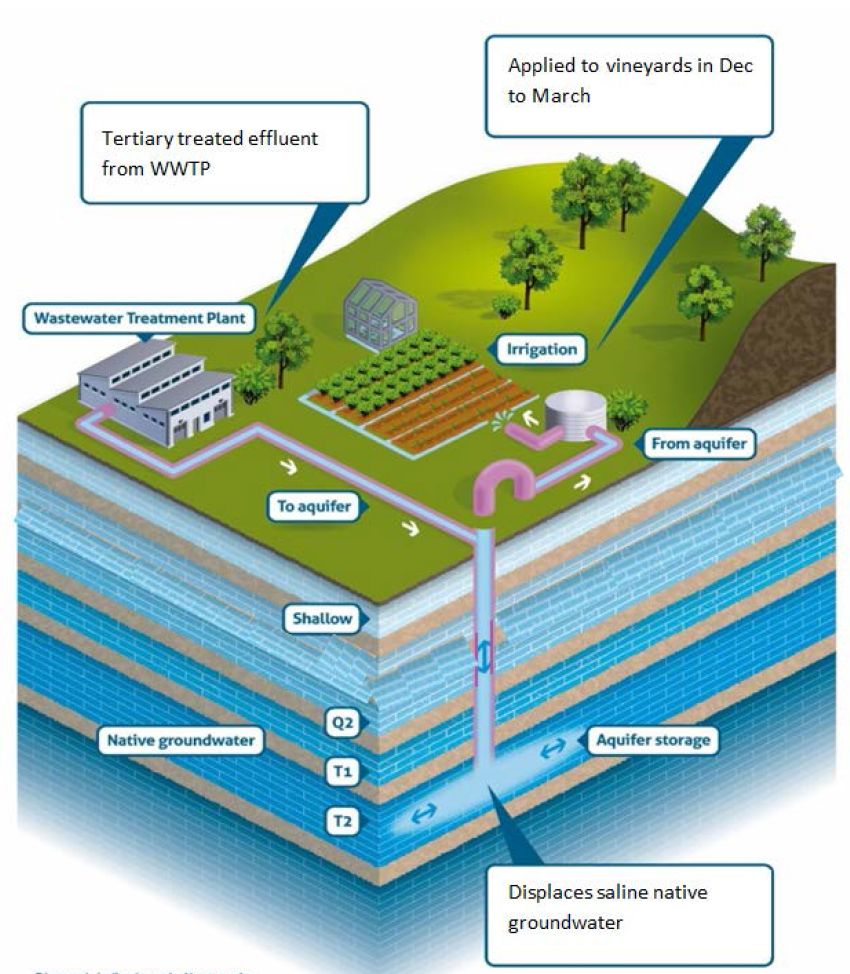

One definition of a managed aquifer recharge scheme is the ability to store treated and recycled water in a subsurface aquifer. Benefits of storing the water in the groundwater is to significantly reduce evaporation losses associated with surface pond storage.

The recycled water is pumped into the ground under pressure and the aim is to displace naturally occurring groundwater in an aquifer. Saline aquifers are commonly targeted for the storage as the salinity levels make the groundwater of little use for irrigation.

With the recycled water in the ground, this irrigation resource can be tapped at a time of the year it is required. For example, winter months pump the recycled water into the aquifer and summer months pump out to increase the irrigation water supply

<h4>Leaky Wells</h4>

As with a water supply bore and its cone of depression during pumping out water, a MAR injection bore will have a similar area of influence. Essentially the injection will cause local artesian conditions as the natural groundwater is displaced.

Ask any water bed owner, a pin prick hole can cause a lot of water wastage. The “pin prick holes” relevant to a MAR scheme are old bores in the area of influence around an injection bore.

<h4>Where are the leaks?</h4>

- Old steel cased linings of bores can degrade over time leading to a loss of integrity and a passage way from water flow from the ground to the surface.

- Many old bores did not have a pressurised cement job at the time of construction. This means there is no barrier between the outside of the casing and the rock. Once again this can be a passage way from water flow from the ground to the surface.

- Poor cementation job during bore construction.

<h4>Geophysical Logging</h4>

Now we understand the importance of sealing “leaky wells” how can we identify them? The answer is to get close and personal through geophysical borehole logging:

- Checking the casing integrity through caliper logging, acoustic and optical imaging.

- Checking the annular fill between the outside of the casing and rock in the bore using fullwave sonic cement bond logging, density logging or temperature logging.

More to come in this series