Geological Applications: Environmental Contamination

“Knowledge of your target’s physical properties will aid in the selection of the most applicable geophysical logging method for your drill program.”

Environmental contamination investigation and monitoring projects are commonplace today as older industrial sites change their land use. It is important for the regualtors and new landowners to know if an appropriate site clean-up has been undertaken to remove any hazardous waste, allowing a trouble free handover. Common industrial waste products are hydrocarbon based.

Environmental contamination investigation projects commonly involve drilling numerous shallow monitoring boreholes to intersect the local groundwater. The monitoring bores typically comprise 50mm PVC casing to the drilled depth, with the bottom few metres having slotted casing to allow groundwater access. Gravel pack, cement and bentonite plugs are used in the casing external annulus to seal off the slotted casing zone, so only groundwater from the slotted interval gets into the casing. Water level monitoring and groundwater sampling is then routine on an ongoing basis in the monitoring bore.

How can geophysical logging help these projects?

Identify the geology (Gamma and Resistivity/Induction-Conductivity)

- If the contaminant is fluid or gaseous, it can only travel with the groundwater or in the vadose zone through the pore space of the rock and structural fractures through faults and/or joints. Equally as important as pore space is the rock permeability or its ability to transmit a fluid. Note that a rock maybe highly porous but have a very low permeability = clay

- The ability to define different rock types intersected by the borehole is important. In a sand/clay sequence, it is the sands which typically have higher porosity and associated permeability and are the likely travel paths for contaminants. Conversely, the clays can act as an aquitard, thus acting as a barrier to contaminant flow.

Simple gamma, resistivity and/or induction-conductivity logging are powerful tools in identifying the local geology in a sand/clay sequence.

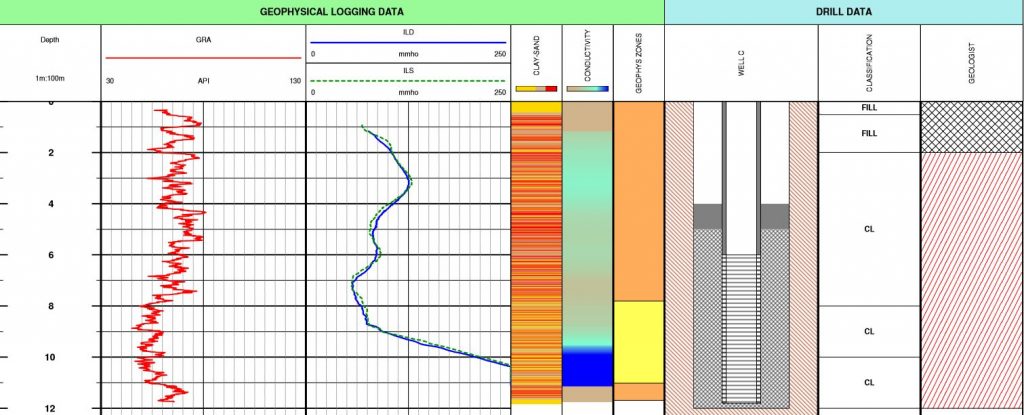

The example above shows a variable sand/silt and clay sequence, typically thin sands within an otherwise clay sequence. The induction-conductivity data shows a conductive body below 10m – so a resistive contaminant above (?). Look at the detail or lack thereof in the geologists log!!

Identify the contaminant

- If the contaminant is hydrocarbon based, then it is likely to have a resistive signature. Within a PVC cased monitoring borehole, induction-conductivity logging is the best method for measuring a resistivity profile. The resistivity profile will reflect changes in the geology from sand to clays and changes in the fluid (groundwater & contaminant) within the pore space. If a hydrocarbon contaminant even partially replaces groundwater in the pore space of the sands, there will be a significant change to the resistivity profile.

- Bear in mind that it is this principle (hydrocarbons replacing groundwater) which the oil industry have exploited for their sophisticated analyses in oil exploration and reservoir development.

Sample the contaminant

- Environmental consultants typically use a small pump in the monitoring bores to provide a surface sample which can be analysed in the laboratory. How certain can you be that the sample is “clean” – not a residue left at the bottom of the bore, and/or is from the appropriate depth in the bore and as such representative of the local conditions?

- The power of geophysical logging is to allow digital sampling “in situ” – from the actual depth of interest. In monitoring bores, this is achieved through water quality logging or an actual fluid sampling probe which can go to any specified depth, capture the sample, then return it intact to the surface.

Geophysical Borehole Logging – Geological Intelligence for Environmental Assessment.