LOGGING PROBE STACKS OVERVIEW:

Cost pressures on the mining industry means contractors are always under pressure to come up with innovative solutions to reduce costs. Geophysical logging is a valued service for mining producing accurate and cost effective data for ore body knowledge and mining solutions. Still the multiple logging runs required for a complete data set, especially when a drill rig is tied up by the service, means questions will always be asked, “Can we do this smarter?”

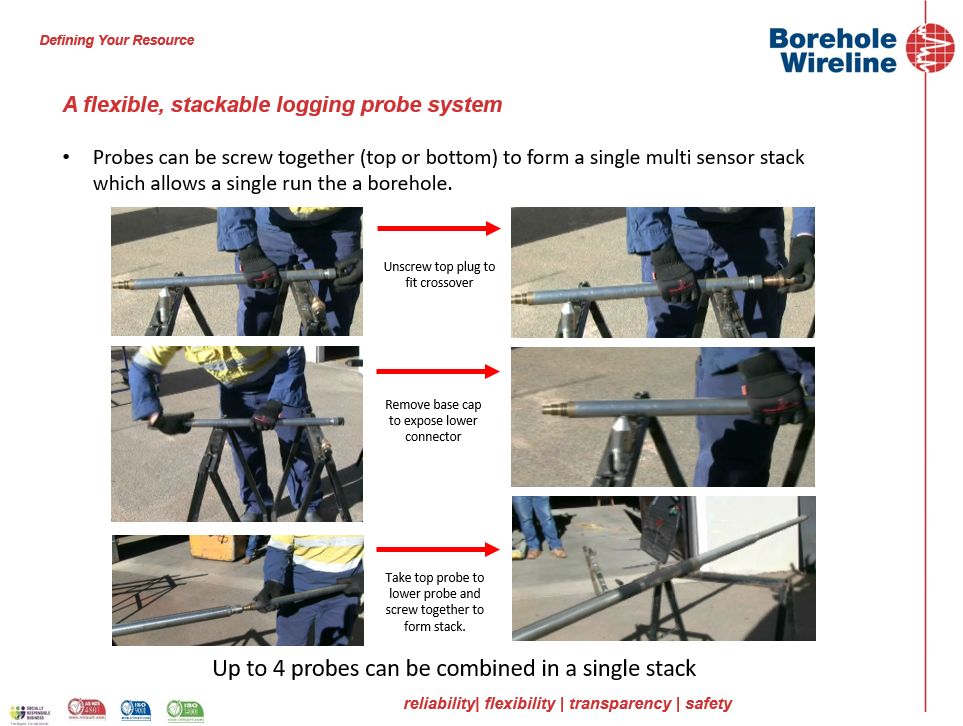

LOGGING PROBE STACKS STACKING SYSTEM:

A logging stack refers to a series of probes screwed together to form a single instrument with multiple sensors. This means a single pass in the borehole. The stack is assembled at the borehole prior to logging operations by a single operator.

LOGGING PROBE STACKS OPERATIONS:

A typical coal logging dataset could require up to 4 or more logging runs and a total of 8 hours to complete with a conventional logging system. Using the logging stack system, the number of runs can be reduced to 1 or 2 with logging completed in less than half the time. A time saving of 50% which means costs are reduced. “Time is Money”.

As an actual example, it is not unusual for a conventional mineral logging operation in coal exploration to have to make an additional logging run for magnetic deviation and potentially another extra logging run for temperature. Using a stacking system both magnetic deviation and temperature can be Incorporated into a single stacks, resulting in only 3 logging runs in a borehole to complete the required dataset.

In theory the arrangement of the logging probes in a stack is up to the user, however there are a few restrictions. For example, typical mineral radioactive probes have the source at the base of the probe, so typically probes cannot be stacked below this point. To overcome this restriction, side loading sources have been designed and are available today.

The logging winch remote system is an aid when the logging stack becomes too long for manual handling by a single operator. This option becomes available when logging off a drill rig or where high reach logging booms are available.

Another plus for the stack logging system is that when a probe fails, only that part of the stack needs to be replaced/repaired. In a conventional logging system if a detector fails then the whole probe has to be replaced/repaired.