Borehole Imaging: Acoustic Scanner (Televiewers) versus 3 or 4 arm dipmeter.

The acoustic scanner and 3 or 4 arm dipmeter probes have been used for coal exploration for a long time. It would be fair to say that the acoustic scanner has superseded the 3 or 4 arm dipmeter as being the preferred method for structural or geotechnical analysis. Both methods have their strengths and weaknesses.

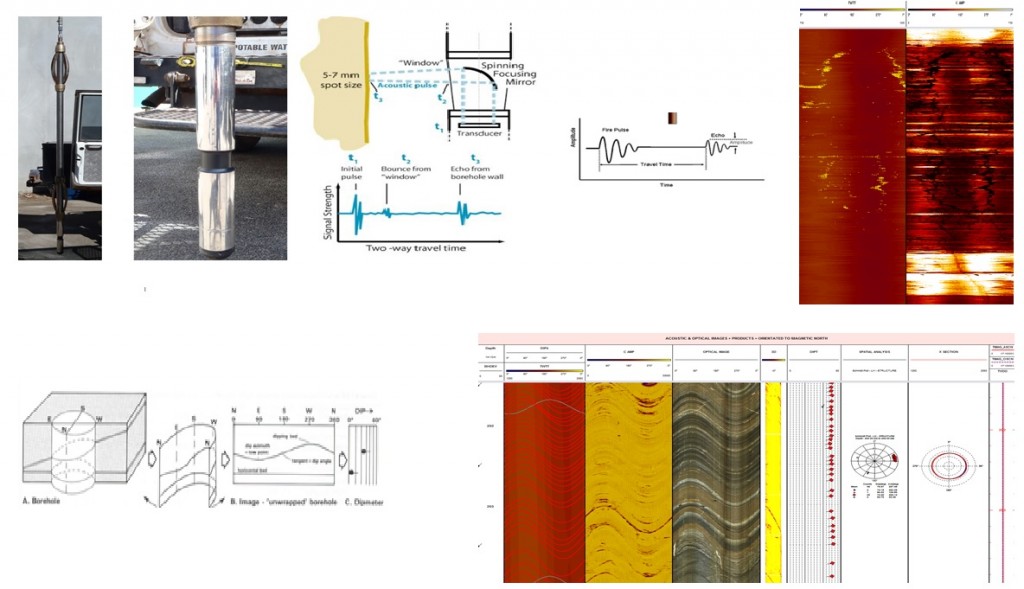

Acoustic Scanner

The acoustic scanner is an acoustic echo imaging device which, under the right conditions, provides an orientated (magnetic north or borehole highside) image of the acoustic impedance borehole wall and a multi-fingered caliper profile. From the resultant travel time and amplitude image, structures can be identified, “picked/orientated” for dip and dip direction and classified into fractures, fabric, veins and so on. At the present day it is a routine service provided by mineral logging companies and a routine requirement in any geotechnical investigation or exploration programme now enhanced by the optical scanner which provides high resolution, true colour images of the borehole wall.

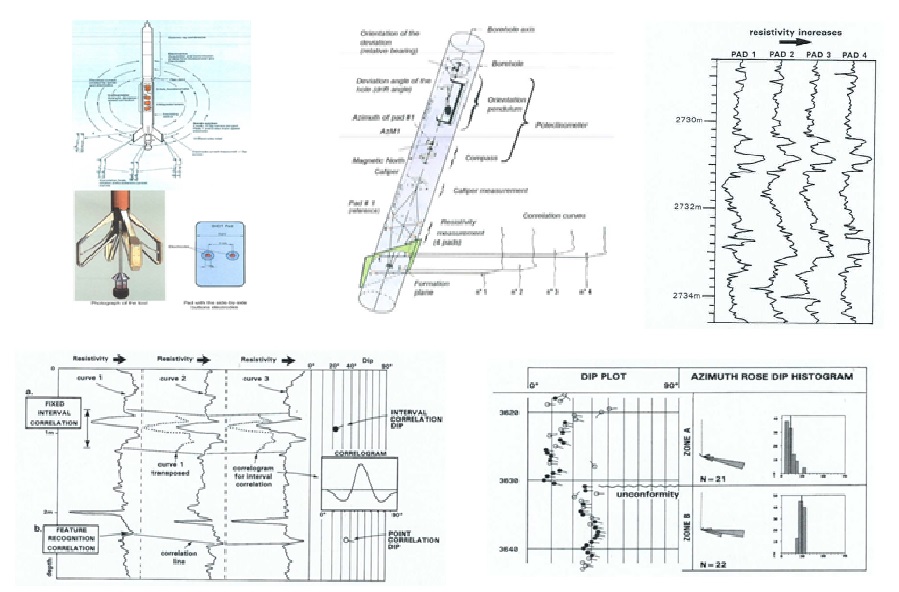

3 or 4 Arm Dipmeter

The mineral logging 3 or 4 arm dipmeter is an electrical device, measuring the resistivity of the borehole wall through three or four pad pushed against the borehole wall. A single resistivity curve is produced from each pad. From the arms of each pad a caliper measurement of the borehole diameter is made. Data processing involves a cross correlation technique to identify patterns in the resistivity curves and resultant dip and dip direction of structures. We should note here that the typical mineral logging dipmeter is quite different to the resistivity imaging probes used by the oil industry which have multiple buttons on each pad to record the borehole wall resistivity. The mineral logging dipmeter is a single measurement per pad.

Whilst the acquisition methods are different, the final outputs appear similar and are of great value to the geologist or geotechnical engineer.

Acoustic Scanner: Strength & Weakness

+ greater coverage of the borehole wall.

+ common availability and applications (cased hole and openhole).

+ structural geology, geotechnical and sedimentological applications.

_ Manual “picking” process for structures.

3 arm dipmeter: Strength & Weakness

+ automated processing. Product available at the logging unit.

+ geologists understand the product.

+ a sedimentological tool.

_ limited coverage of the borehole wall.

_ limited availability (Most logging equipment manufacturer’s do not make the system.

Automated structure “picking” for acoustic images is being developed.

It is not unusual for a dipmeter to be required for coal exploration projects today but with education the geologists can become comfortable with the acoustic scanner method.